Step-by-Step Valve Stem Replacement on a D-Style Keg Coupler

Essential Kegerator Coupler Parts for Your Home Brew Setup

Ever wondered why your draft beer sometimes pours foamy or flat? Those issues often trace back to the little parts that bridge your keg and tap. If you don’t have the proper hardware, even a great beer can go flat and lose its taste.

At Installation Parts Supply, we know that a smooth pour starts with quality hardware. From homebrewers to casual draft-beer fans, getting to know these Sanke keg coupler parts guarantees the perfect pour.

Whether it’s a washer or a length of gas tubing, each piece helps preserve carbonation and flavor. More than nine out of ten pour problems stem from mismatched or worn parts. With a bit of know-how, you can keep your setup working without a hitch.

Notable Observations

- The correct coupler choice means perfect carbonation and flavor.

- Installation Parts Supply offers dependable draft-system hardware.

- Regular maintenance prevents common pouring problems.

- The style of coupler depends on the beer you’re pouring.

- The majority of malfunctions start with coupler problems.

Define the Kegerator Coupler

A flawless draft begins with the proper keg-to-tap link. Think of the keg coupler as the connector between your CO₂ cylinder or nitrogen tank and the beer line, employing pressurized gas to deliver beer flawlessly to your taps. Think of it as the engine of your draft beer system—without it, nothing flows.

That tiny gadget serves a dual purpose: gas delivery to pressurize and valve control to pour your beer. Within its housing is a probe, a check valve, plus dedicated gas and liquid ports. These components work together to maintain carbonation and prevent excess foam.

| Part | Function | Common Issues |

|---|---|---|

| Coupler Probe | Pierces the keg’s cap | Leaks if not aligned properly |

| Return Valve | Prevents backflow | Flat pours from worn seals |

| Gas/Liquid Ports | Connects to lines | Loose fittings create foam |

Attaching the coupler wrong is a rookie mistake—75% of first-time users do it. End results include overflow foam, drips, or wasted brew. Check Installation Parts Supply’s charts and videos for correct setup.

Universal designs mean most couplers work similarly, but always match yours to your keg type. The incorrect coupler not only spoils the beer, it can wreck your setup.

Which Keg Coupler Is Right for You?

Different beers call for different couplers. The correct coupler preserves carbonation and taste. Follow this guide to choose the right one.

D-Type Coupler (Sankey)

It’s used by roughly 85% of U.S. craft breweries. Its single-valve design locks securely onto most domestic kegs. Pro tip: Look for the Sankey name stamped on the side.

U-Type Coupler

Recognizable by its harp logo, this type is a must for nitro beers like Guinness. A 75% nitrogen mix gives you that signature creamy foam. Don’t jam a U-style onto a regular keg—no proper seal results.

European S-Type Coupler

Imports from Europe require this S-system coupler. That reverse threading avoids confusion with standard Sankey. Trivia: It stands a bit taller than the North American model.

A-, G-, and M-Type Couplers

German and UK beers demand specialized connectors:

- A System: Slides onto Warsteiner or Paulaner kegs. The “slider” mechanism is foolproof.

- G System: Used by UK pubs for Bass and Boddingtons. A pub staple across the UK.

- M System: Secures Schneider Weisse barrels. Its click-lock ensures it’s seated.

Their guide highlights D in green, U in black, S in blue. One Midwestern brewery cut costs by $3K annually with the right couplers. Never rely on “universal”—real compatibility wins.

Coupler Parts Breakdown

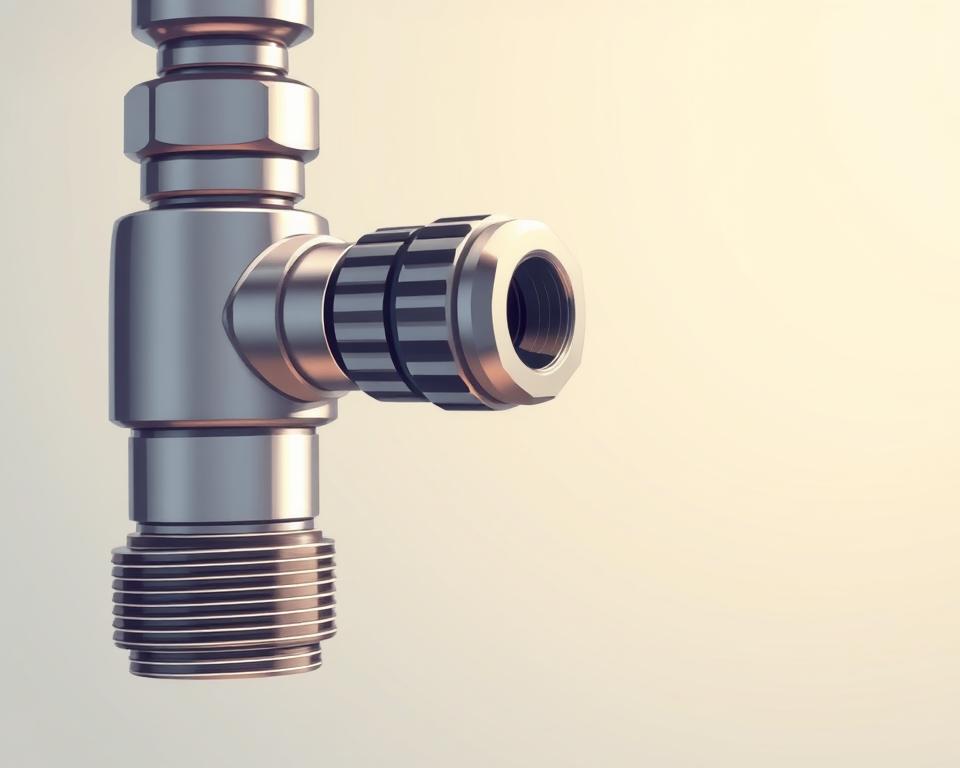

Behind every smooth pour lies a set of precision-engineered components. Together, they keep carbonation in and foam out. Here’s a look at the parts that matter most.

Probe + Return Valve

The metal probe opens the keg’s seal for dispensing. High-end probes outlast budget ones by threefold. The check valve below prevents backflow and is our most swapped component.

Coupler Hex Nut & Washers

Everything tightens up around the hex nut. Brass suits budgets, but stainless steel resists corrosion. Pair it with nitrile washers for cold temperatures—EPDM rubber cracks faster below 40°F.

| Part | Material | Key Benefit |

|---|---|---|

| Coupler Probe | Stainless Steel | Resists wear |

| Return Valve | Food-grade plastic | Prevents flat beer |

| Coupler Nut | Brass/Stainless | Cost-effective & durable |

Gas and Liquid Ports

The gas port handles 20–30 PSI for CO₂ or nitrogen. Incorrect pressure spells foam issues. Use 3/16″ tubing for beer lines; 1/4″ causes extra agitation. Rebuild kits with FDA seals simplify maintenance.

Pro Tip: Swap O-rings every 6 months or 50 kegs. A $3 washer replacement beats a $150 coupler failure.

How to Set Up Your Kegerator Coupler

Getting your draft system right means perfect pours every time. Correct hookups avoid pouring issues. Here’s how to hook it up without hiccups.

Connecting the Coupler to the Keg

Open the handle, fit lugs into place. Twist until firm; don’t over-torque or harm the seal. Choose low-profile to gain 4–5″ clearance.

Our wrench sets hex nuts to the ideal 8-10 ft-lb. Eighty percent of leaks stem from a crooked probe. New washers keep your system sealed.

Hooking Up Your Gas & Beer Lines

Hook the gas line on with 5/16″ fittings. Seal threads to stop CO₂ from escaping. Keep beer tubing 10-12′ of 3/16″ ID for best flow.

| Step | Equipment | Note |

|---|---|---|

| Gas Line | Pipe dope | Test at 30 PSI for bubbles |

| Draft Line | Pipe cutter | Cut straight for proper seals |

| Pressure Test | Leak detector | Check for 24 hours |

Modern rigs offer app-based pressure feedback. Our quick-connects helped a Denver bar slash foam by forty percent. Turn off gas immediately if you spot big leaks.

Troubleshooting Common Coupler Issues

Nothing ruins a cold beer faster than foam spraying everywhere. Once you know what to check, most issues are easy to fix. Here are the usual culprits and how to remedy them.

Leaks and Foamy Beer

Foam is blamed in nearly 70% of draft problems. Start by checking your temperature—ideally 38°F for most ales. Warm beer releases CO₂ prematurely.

Next, inspect your beer line connections. A soapy water solution reveals gas leaks through bubbles. Snug fittings carefully; overtightening can harm seals.

- Check ball failure causes intermittent flow—listen for hissing sounds

- Pressure imbalance? Compare your gauge to this chart:

| Beer Type | CO₂ Pressure | N₂ Ratio |

|---|---|---|

| Lagers | 10–12 | N/A |

| Nitro Stouts | 25–30 | 75% nitrogen |

Loose Coupler Issues

A loose fit often means the O-rings need replacing. Installation Parts Supply reports this fixes 40% of attachment issues. Bent coupler heads sometimes require new units.

Shims can stabilize wobbly connections. They’re a cheap way to stop wobble. Slim couplers fit into tighter kegerators.

Pro Tip: Keep a five-seal washer kit on hand for emergencies. One Chicago pub trimmed loss by 18% with staff training.

If your CO₂ tank frosts up, you’re running too hard. Allow the tank to warm up prior to any valve tweaks. Annual gauge calibration keeps readings true.

Coupler Cleaning & Care

A clean draft system means crisp, fresh-tasting beer every pour. Residue can dull taste and impede flow. A quick cleaning regimen prevents issues.

Taking Apart & Soaking

Start by taking apart the coupler. Take off the handle, pull out the probe and valve. Soak everything in a PBW bath (1 oz per gallon) for about 15–20 minutes. It dissolves yeast and hop deposits.

Installation Parts Supply’s brush set reaches tight spots. Focus on the ball valve—gunk loves to hide there. Flush well to prevent soap residue.

Best Coupler Cleaners

Powdered Brewery Wash excels at safe cleaning. Acids clean quick but may degrade seals. Sound-wave cleaners strip away stubborn grime.

- Drying: Blow dry or wipe with a microfiber towel.

- Disinfecting: Follow FDA CFR 117 guidelines—30 seconds of contact time kills bacteria.

- Logs: Use a log sheet to record each cleaning.

UV sanitation guards seals longer. Always neutralize wastewater—PBW is alkaline and harms pipes. A quick clean routine preserves flavor and longevity.

Final Thoughts

Enjoy crisp, fresh beer by mastering your draft beer system. Matching the right hardware, regular cleaning, and proper setup make all the difference. Installation Parts Supply backs you with expert help and discount rebuild kits.

Did you know? Routine care can extend your equipment’s life by 7 years. Get their checklist and attend a brewmaster session for insider advice. A quick annual inspection ensures trouble-free operation—just ask their 5-year satisfied customers.

Ready to upgrade? Visit Installation Parts Supply today and raise your home bar game.